R1128 C

* Please be kindly noted products are not for therapeutic use. We do not sell to patients.

| Category | Bioactive by-products |

| Catalog number | BBF-03359 |

| CAS | 135161-98-7 |

| Molecular Weight | 326.3 |

| Molecular Formula | C19H18O5 |

Online Inquiry

Description

R1128 C is a non-steroidal estrogen-receptor antagonist produced by Streptomyces sp. No. 1128. The IC50 value of R1128 C for partially purified rat uterine cytosol receptor was 2.6 x 10(-7) M.

Specification

| Synonyms | R1128C; R-1128C |

| IUPAC Name | 1,3,6-trihydroxy-8-(3-methylbutyl)anthracene-9,10-dione |

| Canonical SMILES | CC(C)CCC1=C2C(=CC(=C1)O)C(=O)C3=C(C2=O)C(=CC(=C3)O)O |

| InChI | InChI=1S/C19H18O5/c1-9(2)3-4-10-5-11(20)6-13-16(10)19(24)17-14(18(13)23)7-12(21)8-15(17)22/h5-9,20-22H,3-4H2,1-2H3 |

| InChI Key | HQIGXKMUTUJEER-UHFFFAOYSA-N |

Properties

| Appearance | Brown Powder |

| Melting Point | 240-245°C |

Reference Reading

1. De novo biosynthesis of carminic acid in Saccharomyces cerevisiae

Qian Zhang, Xinglong Wang, Weizhu Zeng, Sha Xu, Dong Li, Shiqin Yu, Jingwen Zhou Metab Eng. 2023 Jan 10;76:50-62. doi: 10.1016/j.ymben.2023.01.005. Online ahead of print.

Carminic acid is a natural red dye extracted from the insect Dactylopius coccus. Due to its ideal dying effect and high safety, it is widely used in food and cosmetics industries. Previous study showed that introduction of polyketide synthase (OKS) from Aloe arborescens, cyclase (ZhuI) and aromatase (ZhuJ) from Streptomyces sp. R1128, and C-glucosyltransferase (UGT2) from D. coccus into Aspergillus nidulans could achieve trace amounts of de novo production. These four genes were introduced into Saccharomyces cerevisiae, but carminic acid was not detected. Analysis of the genome of A. nidulans revealed that 4'-phosphopantetheinyl transferase (NpgA) and monooxygenase (AptC) are essential for de novo biosynthesis of carminic acid in S. cerevisiae. Additionally, endogenous hydroxylase (Cat5) from S. cerevisiae was found to be responsible for hydroxylation of flavokermesic acid to kermesic acid. Therefore, all enzymes and their functions in the biosynthesis of carminic acid were explored and reconstructed in S. cerevisiae. Through systematic pathway engineering, including regulating enzyme expression, enhancing precursor supply, and modifying the β-oxidation pathway, the carminic acid titer in a 5 L bioreactor reached 7580.9 μg/L, the highest yet reported for a microorganism. Heterologous reconstruction of the carminic acid biosynthetic pathway in S. cerevisiae has great potential for de novo biosynthesis of anthraquinone dye.

2. Production of Carminic Acid by Metabolically Engineered Escherichia coli

Dongsoo Yang, Woo Dae Jang, Sang Yup Lee J Am Chem Soc. 2021 Apr 14;143(14):5364-5377. doi: 10.1021/jacs.0c12406. Epub 2021 Apr 2.

Carminic acid is an aromatic polyketide found in scale insects (i.e., Dactylopius coccus) and is a widely used natural red colorant. It has long been produced by the cumbersome farming of insects followed by multistep purification processes. Thus, there has been much interest in producing carminic acid by the fermentation of engineered bacteria. Here we report the complete biosynthesis of carminic acid from glucose in engineered Escherichia coli. We first optimized the type II polyketide synthase machinery from Photorhabdus luminescens, enabling a high-level production of flavokermesic acid upon coexpression of the cyclases ZhuI and ZhuJ from Streptomyces sp. R1128. To discover the enzymes responsible for the remaining two reactions (hydroxylation and C-glucosylation), biochemical reaction analyses were performed by testing enzyme candidates reported to perform similar reactions. The two identified enzymes, aklavinone 12-hydroxylase (DnrF) from Streptomyces peucetius and C-glucosyltransferase (GtCGT) from Gentiana triflora, could successfully perform hydroxylation and C-glucosylation of flavokermesic acid, respectively. Then, homology modeling and docking simulations were performed to enhance the activities of these two enzymes, leading to the generation of beneficial mutants with 2-5-fold enhanced conversion efficiencies. In addition, the GtCGT mutant was found to be a generally applicable C-glucosyltransferase in E. coli, as was showcased by the successful production of aloesin found in Aloe vera. Simple metabolic engineering followed by fed-batch fermentation resulted in 0.63 ± 0.02 mg/L of carminic acid production from glucose. The strategies described here will be useful for the design and construction of biosynthetic pathways involving unknown enzymes and consequently the production of diverse industrially important natural products.

3. Synthesis of C-Glucosylated Octaketide Anthraquinones in Nicotiana benthamiana by Using a Multispecies-Based Biosynthetic Pathway

Johan Andersen-Ranberg, Kenneth Thermann Kongstad, Majse Nafisi, Dan Staerk, Finn Thyge Okkels, Uffe Hasbro Mortensen, Birger Lindberg Møller, Rasmus John Normand Frandsen, Rubini Kannangara Chembiochem. 2017 Oct 5;18(19):1893-1897. doi: 10.1002/cbic.201700331. Epub 2017 Aug 21.

Carminic acid is a C-glucosylated octaketide anthraquinone and the main constituent of the natural dye carmine (E120), possessing unique coloring, stability, and solubility properties. Despite being used since ancient times, longstanding efforts to elucidate its route of biosynthesis have been unsuccessful. Herein, a novel combination of enzymes derived from a plant (Aloe arborescens, Aa), a bacterium (Streptomyces sp. R1128, St), and an insect (Dactylopius coccus, Dc) that allows for the biosynthesis of the C-glucosylated anthraquinone, dcII, a precursor for carminic acid, is reported. The pathway, which consists of AaOKS, StZhuI, StZhuJ, and DcUGT2, presents an alternative biosynthetic approach for the production of polyketides by using a type III polyketide synthase (PKS) and tailoring enzymes originating from a type II PKS system. The current study showcases the power of using transient expression in Nicotiana benthamiana for efficient and rapid identification of functional biosynthetic pathways, including both soluble and membrane-bound enzymes.

Recommended Products

| BBF-03755 | Actinomycin D | Inquiry |

| BBF-01826 | Deoxymannojirimycin | Inquiry |

| BBF-00764 | Cerebroside C | Inquiry |

| BBF-00677 | 3-Amino-3-deoxy-D-glucose | Inquiry |

| BBF-01693 | Doxorubicin EP Impurity A (Daunorubicin) | Inquiry |

| BBF-01825 | Loganin | Inquiry |

Bio Calculators

* Our calculator is based on the following equation:

Concentration (start) x Volume (start) = Concentration (final) x Volume (final)

It is commonly abbreviated as: C1V1 = C2V2

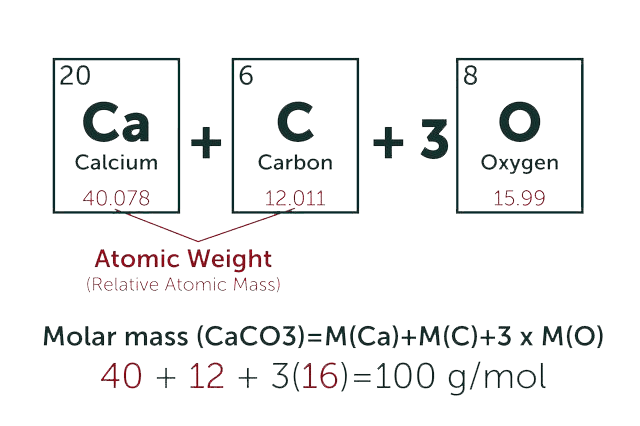

* Total Molecular Weight:

g/mol

Tip: Chemical formula is case sensitive. C22H30N4O √ c22h30n40 ╳